Tracing the footsteps of Jimmy Barnes on the ‘working class man’ tour of Port Kembla Steelworks

It was more than 50 years ago that I last toured the Port Kembla Steelworks, as a primary school kid from Dapto. Who’d have thought all these years later I’d be back in what is now a very different steelmaking plant with a group of town...

It was more than 50 years ago that I last toured the Port Kembla Steelworks, as a primary school kid from Dapto.

Who’d have thought all these years later I’d be back in what is now a very different steelmaking plant with a group of town planners, tracing the footsteps of Australia’s best known ‘working class man’, Jimmy Barnes.

That’s exactly what happened during our special behind-the-scenes tour of Bluescope’s Port Kembla Steelworks last week on the opening day of the Planning Institute of Australia’s 2024 NSW conference.

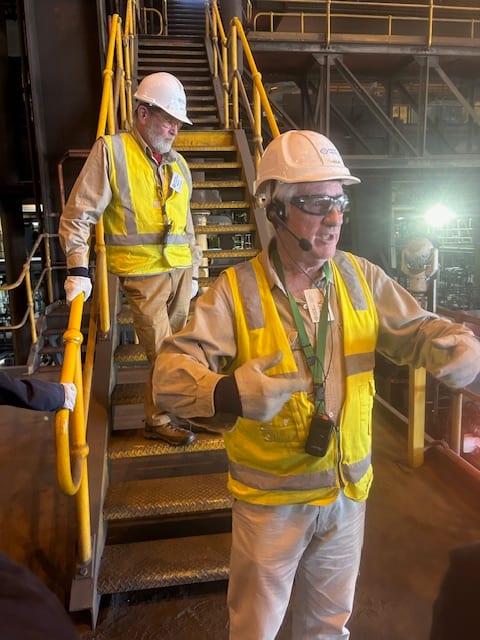

While others headed off for a leisurely heritage stroll along Wollongong’s famed coastal Blue Mile and marvelled at the region’s newest attraction, the Shell Cove Marina, a dozen of us put on our protective helmets, glasses, gloves and coats to get down and dirty at the steelworks.

Our tour was led by two veterans of steelmaking, Rick Bonnor from Figtree and Bob Nightingale from Thirroul, who started working at the plant as teenagers in the early 1970s. Between them they’ve clocked up 100 years at the giant complex, the largest industrial site in Australia.

Safety drills completed, we headed off for a two-hour journey of learning with plenty of ‘oohs’ and ‘aahs’ thrown in as we passed through where the steelmaking is at its most dramatic.

One of those locations is the spectacular BOS (formerly the open hearth) factory. That’s where in 1985 Jimmy Barnes recorded the spectacular video for his hit single, Working Class Man, with much less protection than we were required to wear on our visit. The molten steel is heated to about 1600 degrees Celsius in the process with sparks flying as temperatures reach their peak.

The BOS has replaced the old open hearth and today it produces the same quantity of steel in 30 minutes which took six hours back in the 70s.

There are so many signs of how much steelmaking has changed since I last toured the steelworks as a primary school kid in the early 1970s and when Rick and Bob started their careers.

Bob laughed when he recalled visiting the steelworks on a school excursion when he was about 15. “I remember going home and telling Mum it was a terrible place.”

Two years later he was back as a metallurgy trainee. “In those days I helped out as a tour guide, which was one of the jobs of the first-year trainees, even though we didn’t know very much.”

Fellow guide Rick had retired for six years before seeing an ad on the TV looking for steelworks tour guides and he thought why not, kicking off his part-time job earlier this year.

Between them it seems there’s nothing about the steelworks Bob and Rick don’t know.

Technology and automation has seen a huge drop in the size of the workforce – from 24,000 at its peak to about 3500 today.

Fifty years ago, most of the water used in the process was piped fresh from nearby dams. Today, recycled water makes up the majority, with some saltwater used in the cooling process.

As our bus took us along Iron Ore Road into Hot Strip Road, we saw work well underway on the rebuild of the No. 6 blast furnace, which is towered over by the largest power crane in the southern hemisphere, costing a whopping $40,000 a week to hire. The blast furnace relining is due to be completed in 2026 at a total budget of $1.15 billion.

The Planning Institute of Australia’s national policy director, John Brockhoff, once had family working at the steelworks, but this was his first tour.

"The steelworks is iconic and you’ve got to understand the history of a town to really get into its planning," he said.

“So much of Wollongong’s history as a working town revolves around its heavy industry and while the steelworks still plays its role, Wollongong is now a knowledge-based city with the university going gangbusters.”

With our guides Bob and Rick playing tag team, commentating in turns on and off the bus, we learned that steel is the most recycled material in the world and it can be, and is, recycled multiple times.

There’s also an exciting new opportunity for Bluescope. The company has just released a master plan for a vacant 200-hectare site adjacent to the steelworks to create a next generation multi-industrial precinct with the potential to create thousands of jobs in existing and emerging industries.

The final stop on our tour was at the strip mill that was commissioned in 1958 and, at about 1.5 kilometres long, it remains the biggest industrial building in Australia.

As you’d expect on a steelworks tour, it was hot, dusty, smelly and dirty; but nowhere near as dirty as I remember from my schoolboy tour, 50 or so years ago.

Three Environment Protection Authority (EPA) officers are based on site working together with about a dozen Bluescope environmental staff to ensure the business operates by minimising pollution. It’s a far cry from the first 50 years.

Year on year, the plant works to reduce its carbon footprint and the blast furnace relining currently underway includes new measures to reduce carbon emissions.

Vanessa Morschel from Balgownie found her steelworks tour "insightful". “After how many decades of driving past this place it was great to see what actually goes on inside these buildings.”

Willem Van Wyk from Coalcliff was “surprised by the scale of it and inspired by the ingenuity. It’s also hotter than I expected. I can see that big smokestack from my place and it’s good to know what causes it. Now I know it’s actually steam, not smoke.”

Ingrid Berzins from Lake Illawarra South said: “It’s been great to see such a big industrial site up close. It’s been fascinating and well worth a visit.”

Bluescope runs public tours of the plant with a small charge every second Thursday evening and every Friday and Saturday. Also available are special Clean Energy Tours.

Read more: Beyond Zero Emissions CEO rates the Gong after Clean Tech Tour